BOYSEN EPOXY ENAMEL #2132 GRAY w/ CATALYST 4LTR/GAL

₱1,289.00

DESCRIPTION: BOYSEN® Epoxy Enamel is a high quality, two-component, epoxy-polyamide system that has excellent corrosion resistance and sealing properties. Highly alkali-resistant so there is no need for neutralization of new concrete.

PRINCIPAL USES: As a topcoat for BOYSEN® Epoxy Primer that can be applied on interior surfaces such as metal, galvanized iron, wood and masonry.

PRACTICAL COVERAGE: 20-30 square meter / 4 liters / coat

SURFACE DRY: 2-3 hours

DRY THROUGH: 6-8 hours

DRY FILM THICKNESS: 1.5 mils/coat

THINNING: BOYSEN® Epoxy Reducer #55

APPLICATION: By paint brush or spray gun

PACKAGING: BOYSEN® Epoxy Enamel comes in 4-liter cans, ¾ full packed with curing agent in 1-liter can.

MIXING RATIO: 3:1, paint-to-catalyst, respectively

SURFACE PREPARATION:

Concrete Flooring:

Remove oil and grease by detergent cleaning. For smooth surfaces, acid etch to improve adhesion. Do this by mixing one (1) part muriatic acid to one (1) part water. Apply over masonry and let stand for 2-3 minutes. Rinse with water to remove residual acid. If possible, rinse by pressure washing.

Finished acid etched texture should be similar to that of 40-60 grit sandpaper. Make sure that the surfaces to be painted are clean and dry.

Caution: Adequate protection and ventilation should be provided when working!

Metal:

Wipe the surface with rag soaked in paint thinner to remove dust, dirt, grease, oil, wax and other foreign matter. For new G.I. sheets, etch the surface by applying 10% BOYSEN® Metal Etching Solution #71 (dilute 1 part of B-71 to 9 parts water).

If repainting on surfaces with alkyd or lacquer-based coatings, scrape off all paint film to bare substrate. Remove oil and grease by detergent cleaning followed by scuff sanding. To remove rust, wire brush or scrape affected areas and apply BOYSEN® Metal Etching Solution #71 over rusted portions. Let it stay for 10 – 15 minutes. Be sure to wash off surface thoroughly with water, letting it dry before applying paint. Primer should be applied immediately upon drying of the surface before rust sets in.

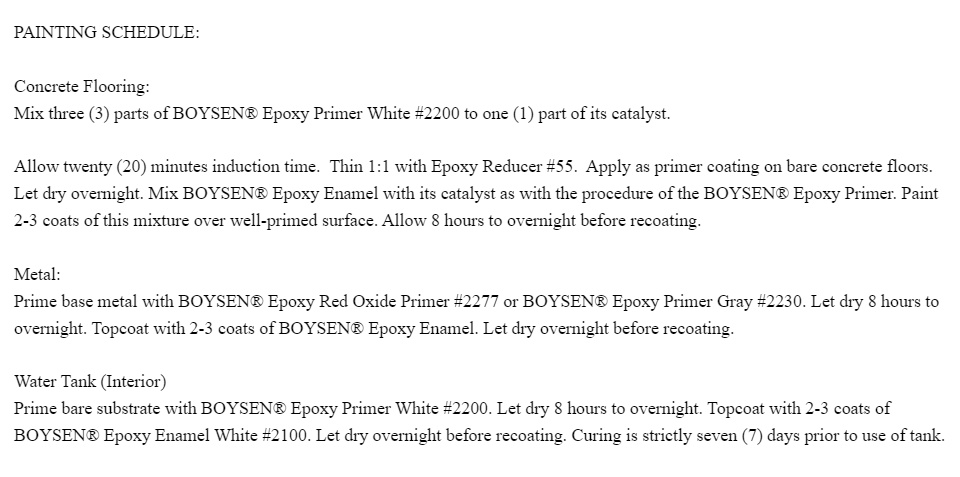

PAINTING SCHEDULE:

Concrete Flooring:

Mix three (3) parts of BOYSEN® Epoxy Primer White #2200 to one (1) part of its catalyst.

Allow twenty (20) minutes induction time. Thin 1:1 with Epoxy Reducer #55. Apply as primer coating on bare concrete floors. Let dry overnight. Mix BOYSEN® Epoxy Enamel with its catalyst as with the procedure of the BOYSEN® Epoxy Primer. Paint 2-3 coats of this mixture over well-primed surface. Allow 8 hours to overnight before recoating.

Metal:

Prime base metal with BOYSEN® Epoxy Red Oxide Primer #2277 or BOYSEN® Epoxy Primer Gray #2230. Let dry 8 hours to overnight. Topcoat with 2-3 coats of BOYSEN® Epoxy Enamel. Let dry overnight before recoating.

Water Tank (Interior)

Prime bare substrate with BOYSEN® Epoxy Primer White #2200. Let dry 8 hours to overnight. Topcoat with 2-3 coats of BOYSEN® Epoxy Enamel White #2100. Let dry overnight before recoating. Curing is strictly seven (7) days prior to use of tank.

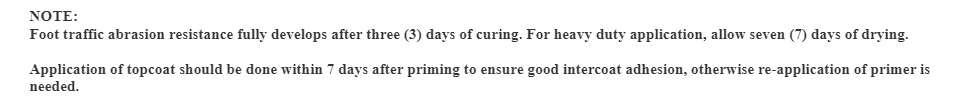

NOTE:

Foot traffic abrasion resistance fully develops after three (3) days of curing. For heavy duty application, allow seven (7) days of drying.

Application of topcoat should be done within 7 days after priming to ensure good intercoat adhesion, otherwise re-application of primer is needed.

- Description

- Additional information

- Reviews (0)

Description

Additional information

| Weight | 3 kg |

|---|---|

| Dimensions | 3.00 × 5.00 × 8.00 cm |

| brand | boysen |

| paint_finish | matt |

| paint_type | interior & exterior metal primer |

| model | #2132 |

| preorder | no |

| source | asc |

Reviews

There are no reviews yet.